How an OMS transforms stock and order management

As sales channels diversify and consumer expectations rise, efficient stock management becomes critical. Retailers need real-time stock visibility and a unified product overview to stay competitive. An Order Management System (OMS) addresses these needs by centralizing information and orchestrating order and stock flow.

This article illustrates how an OMS revolutionizes stock management and enables brands to deliver a seamless shopping experience.

Key takeaways

- The unification of stock and order management across all channels with OMS.

- Allocation rules that minimize stockouts and reduce withdrawal times.

- The strategic advantage of integrating OMS in retail logistics.

Transforming stock management with an OMS

Understanding OMS functionality

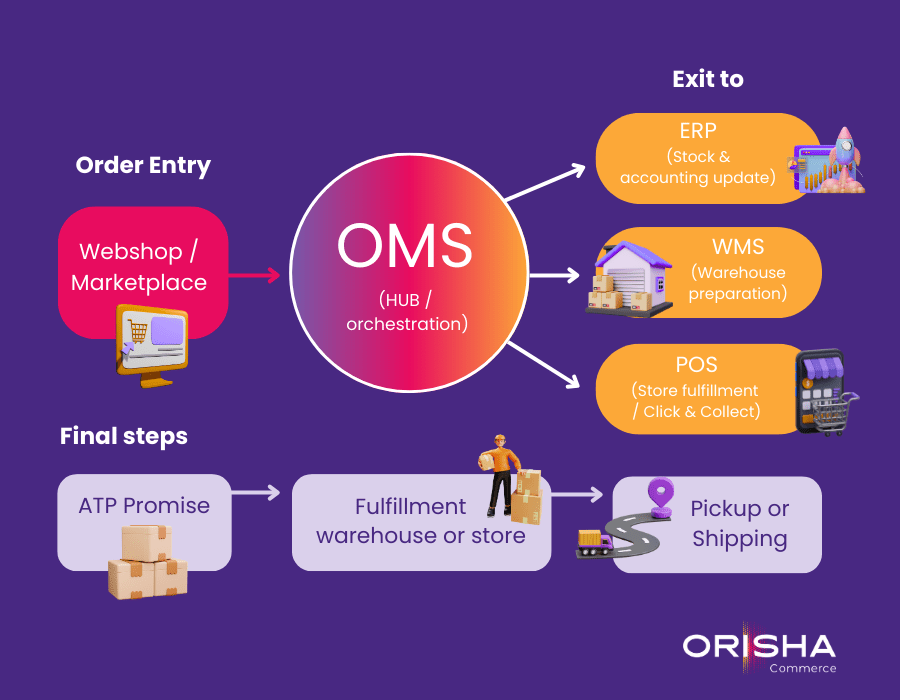

An Order Management System (OMS) centralizes order management across all sales channels including e-commerce logistics, physical stores, marketplaces, and click and collect. It orchestrates the flow of orders and stock, offering a unified view of product availability.

The OMS collects real-time data from various storage points such as warehouses, stores, and logistics partners to provide a single stock view. It allows for:

- Synchronization of stock across all channels.

- Order allocation based on customer location and current stock status.

- Automation of logistics flows to minimize errors and expedite order processing.

An OMS converts fragmented management into a cohesive system, ensuring a seamless shopping experience.

OMS vs WMS vs ERP: roles defined

- ERP oversees processes such as purchasing, finance, and product reference.

- WMS handles warehouse operations like receiving, picking, and shipping.

- OMS coordinates orders across different channels and stock locations (stores, warehouses, marketplaces) using allocation rules and availability assurances.

The importance of unified stock management

A unified stock management strategy views all inventories as a single reservoir, accessible from all sales channels, aiming to eliminate silos and improve visibility.

Companies benefit significantly from unified stock management:

- Reducing stockouts: dispersed inventory often results in products being unavailable online though available in some stores.

- Enhancing product availability: a unified stock enables items to be offered from any selling point, increasing conversion rates.

- Optimizing stock and logistics costs: intelligent orchestration of shipments reduces transport costs and inventory surplus.

The Openbravo SSMS solution addresses these challenges by integrating centralized stock management with advanced flow orchestration. It provides comprehensive inventory visibility and guarantees efficient order processing across all purchase channels.

Choosing the right Order Management System (OMS)

Evaluate the following:

- Allocation rules: Ensure they consider costs, delays, logistical capacities, and commercial priorities.

- Connectivity: Check for seamless integration with existing systems (POS, ERP, WMS, marketplaces) through APIs or webhooks.

- Real-time performance: Look for low latency and instant synchronization of stock and order data.

- Management and observability: Access key performance indicators (KPIs) to monitor performance and pinpoint bottlenecks.

- Total cost of ownership (TCO): Assess license, integration, and maintenance costs to forecast project profitability.

Optimizing product availability

Ensuring efficient replenishment

Poorly managed replenishment results in empty shelves, prolonged online delays, and lost sales. An OMS counters these issues by automating the reordering process.

By providing an integrated view of the stock, OMS anticipates store needs and initiates replenishments prior to stockouts. It considers:

- Current inventory levels.

- Demand forecasts based on historical data and trends.

- Supplier lead times.

- Logistical capacities.

Automation minimizes errors, ensuring that the right products reach the right place at the right time.

Minimizing stock interruptions

33% of French consumers believe brands should improve product availability in stores, and 26% feel the same about online availability. Stock interruptions erode customer trust.

An OMS serves as a protective measure against these interruptions, utilizing three core strategies:

- Proactive alerts: The OMS identifies critical thresholds and alerts potential stockout risks in advance.

- Dynamic order reallocation: When stock depletes at one location, the OMS automatically redirects the order to another available point.

- Flexible priority management: Balancing needs across channels to address urgent demands without sacrificing profitability.

OMS Pricing

Costs vary based on the SaaS model (license + consumption), integrations (POS, ERP, WMS, marketplaces), project setup (configuration, rules, tests), and operational maintenance (MCO, SLA). Start with a limited pilot to assess the total cost of ownership (TCO) before scaling up.

Enhancing the shopping experience through advanced logistics

Real-time order management

In an omnichannel setting, real-time order processing is a key differentiator. Stock management software offers responsive service by centralizing information flows on one platform.

Orders are tracked instantly, from payment confirmation to delivery or in-store pickup. The OMS consistently updates stocks, preventing the sale of unavailable items.

This results in:

- Trustworthy delivery services.

- Precise notifications at each stage.

- Flexible options for withdrawal or shipping.

Streamlining product preparation and shipping

An OMS streamlines the preparation, shipping, and tracking phases of customer orders by coordinating operations through centralized data.

The OMS directs order preparation to the warehouse or store nearest the customer. It enhances picking processes with updated instructions for onsite teams and automates labeling and carrier management for deliveries. This streamlining ensures deadlines are met.

Openbravo SSMS takes logistics management a step further. The solution connects stocks and operations in stores in real-time, simplifying the preparation and delivery of customer orders.

Rolcar enhances stock management across repair workshops

“Openbravo has significantly improved our understanding of product sales performance and client interactions, as well as inventory processes in our repair workshops. This improvement has made us more competitive in the market.” Victor Manuel López, President and General Director of Administration and Finance at Rolcar

Ensuring precise inventory control

Utilizing modern tracking tools

In an omnichannel environment, each stockout affects the customer experience, making precise inventory management crucial. Traditional methods using manual updates or isolated systems are inadequate in today’s complex setting.

An OMS optimizes stock management through automated tracking, relying on technologies like APIs for instant data exchange, mobile scanners for reliable stock movements, and IoT for continuous inventory monitoring across the network.

This digitalization provides teams with real-time product visibility, enabling them to promptly rectify inventory discrepancies and adjust replenishments.

Integration ease with Openbravo SSMS

Openbravo SSMS seamlessly integrates with existing systems, enhanced by additional modules to cover all management processes. Its connectivity enables synchronization with ERP, OMS, and other tools, while offering advanced features like flexible stock counting, customer returns management, and internal movements.

Which KPIs to

Which KPIs to monitor with an OMS?

- OTIF (On Time In Full).

- Fill rate.

- Cancellation rate.

- Click and Collect lead time.

- % Ship-from-Store.

- Promise kept (ATP/CTP).

- Post-allocation margins.

- Avoided logistical costs.

Monitor these KPIs by channel and allocation rule to track improvements.

Explore formulas for effective stock management!

Maximizing stock management capacity

Unified stock management leverages each unit to meet market needs effectively. An OMS enhances this capability by efficiently managing resources:

- Utilizing each storage point actively, treating stores as mini-warehouses.

- Allocating order flows based on costs, delays, and commercial priorities.

- Adapting stock strategies in real-time with predictive analysis to respond to customer demand variations.

Maximizing stock utilization

Maximizing stock means ensuring every unit in your network is working to meet customer demand. An OMS optimizes this potential by treating all resources no matter where they areas part of the fulfillment engine:

- Every storage location becomes an active asset, with stores operating as mini‑distribution hubs

- Orders are dynamically allocated based on cost, lead time, and strategic priorities

- Stock strategies adapt in real time to fluctuations in demand, powered by predictive analytics

Adopting an Order Management System revolutionizes how brands manage stock and fulfill customer expectations. An OMS guarantees improved product availability, fewer stockouts, and optimized logistics costs.

Brands that implement this strategy boost their efficiency and secure each stage of the customer journey. With its precision and responsiveness, Openbravo SSMS enables brands to convert their stock into a competitive advantage.

Frequently asked questions

How does an OMS work?

An OMS consolidates all order and inventory data onto a single platform. It keeps information synchronized across every sales channel, automatically routes each order to the most suitable fulfillment point, and optimizes the movement of goods through your logistics network.

How can an OMS improve inventory management?

By giving retailers a unified, real‑time view of all inventory, an OMS makes it easier to prevent stockouts, reallocate orders dynamically to where stock is available, and fine‑tune replenishment processes for maximum efficiency.

What are the benefits of using an OMS for unified commerce?

For unified commerce strategies, an OMS delivers major advantages:

- – A single, real‑time view of stock across the whole network

- – Improved product availability, driving better customer experiences

- – Fewer stockouts and lower logistics costs

- – Easy integration with existing store and enterprise systems

- – A seamless journey from checkout through to delivery or collection