Logistics automation: enhancing warehouse management in unified commerce

As omnichannel commerce continues to grow, logistics face increasing pressure due to short deadlines, high volumes, and the need for coordination across channels. Automation is essential to streamline processes and ensure quick, reliable deliveries. This article explores the concrete benefits of logistics automation within a unified commerce framework.

The significance of logistics automation

What are the challenges of logistics automation?

Logistics play a pivotal role in business performance. Managing the flow of items across a website, multiple stores, warehouses, and pick-up points simultaneously demands both precision and responsiveness. Automation solutions are essential to cope with increasing volumes while ensuring smooth synchronization across channels. Research indicates that implementing logistics automation can reduce logistics costs by 30% and speed up delivery times by more than 20%.

Unified commerce platforms create a cohesive ecosystem by interconnecting various touchpoints, storage zones, and management tools. Central to this system is the unified WMS, which orchestrates inventory management, shipment tracking, and order prioritization based on their originating channel.

Advantages for e-commerce

In the realm of e-commerce, the assurance of speed and reliability is critical to purchasing decisions. Indeed, four out of ten consumers abandon their shopping carts if perceived delivery times are too lengthy or if they lack confidence in the process.

Automated logistics accelerate order processing and minimize shipping errors. Furthermore, these tools synchronize logistics operations across all channels, reducing the risks of stockouts or excess inventory through a unified stock system.

Enhanced transparency fosters customer trust by providing reliable product availability information. Additionally, automation simplifies return management.

Impacts on the supply chain

Automation in logistics enhances fluidity and adaptability across supply chains. Data flows effortlessly between suppliers, warehouses, and points of sale, thereby reducing coordination times.

Such coherence improves responsiveness to unexpected events. For instance, if a supplier experiences delays, an automated system can suggest alternate storage allocations to prevent stockouts. Additionally, real-time data analysis sharpens forecasting capabilities.

Key technologies in automation

Automated systems and their functions

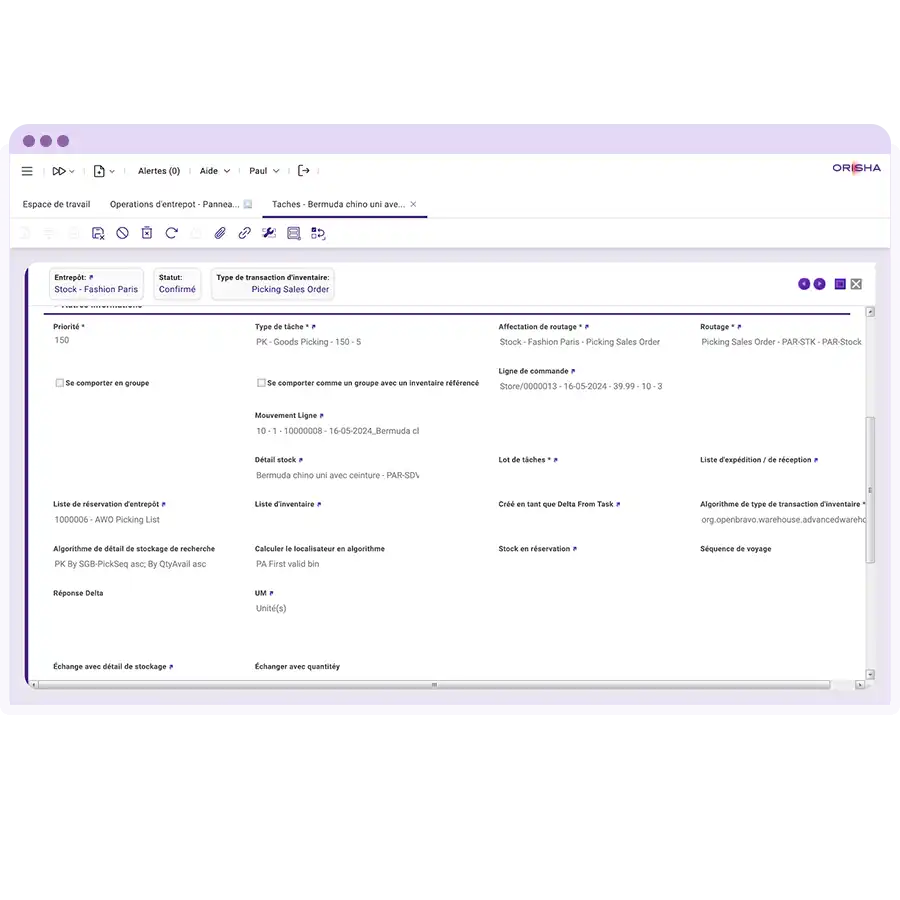

A crucial component of logistics automation is the WMS, which oversees warehouse operations including reception, storage, order preparation, and shipment. It employs optimization algorithms to efficiently delegate tasks and minimize movement.

In warehouses, automated conveyance systems and autonomous robots facilitate the handling of goods, thereby reducing physical strain and processing time per order. Coordinated with the WMS, these technologies operate in concert.

Planning software adjusts priorities and handles unexpected events using artificial intelligence. In addition, automatic identification technologies such as RFID systems ensure comprehensive traceability of goods.

Openbravo WMS integrates multiple efficiency mechanisms in a single solution:

- Real-time stock alert automation;

- Streamlined order management;

Effortless integration with logistics partners via robust APIs.

Its open architecture simplifies implementation and ensures fluid information flow throughout the company’s entire chain.

Request a demo of our software!

Essential features and their benefits

Logistics automation encompasses various features that revolutionize operational management for businesses. Real-time automation enables immediate response to events along the logistics chain:

- A stockout prompts an alert;

- A carrier delay redirects a shipment;

- An urgent order receives automatic prioritization.

Delivery and order management are crucial aspects. Automation allows for analyzing each order by type, originating channel, urgency, and available inventory. Based on this analysis, the system chooses the most suitable processing mode: warehouse shipment, in-store preparation, or split shipment.

API integration with logistics providers streamlines automated exchanges with carriers, preparation hubs, or distribution centers. This connectivity, established during installation, enhances operation tracking.

Enhancing warehouse operations

Effective order preparation strategies

Automating the order preparation stage can significantly improve efficiency. A well-designed warehouse layout minimizes unnecessary movements, facilitated by a WMS that updates distribution rules dynamically.

Companies can implement various automated picking methods:

- Batch picking to consolidate trips;

- Zone picking to segment the warehouse into specialized zones;

- Wave picking to organize shipments in batches.

Guidance technologies further enhance precision and speed. Combined with automated control systems, they ensure real-time validation and eliminate extensive quality control measures.

Looking to manage your warehouse’s performance with precision? Explore the Openbravo WMS software!

Enhancing sorting and goods retrieval

During procurement, automated systems take charge of controlling, identifying, and directing goods. Scanners, RFID portals, and connected scales analyze parcels, thus reducing errors and time needed to stock items. Depending on product characteristics, destination, or priority, items are automatically redirected to the appropriate zone.

For retrieving stored items, “goods-to-person” technologies invert traditional picking logic: instead of operators moving to products, products move to them.

Managing flows and storage

Automation enables the synchronization of all company flows while offering optimized stock tracking. This allows brands to manage their entire inventories, whether in warehouses or stores, and provide more flexible distribution options.

Inventory rationalization depends on improved anticipation of customer needs. Using sales histories and forecasts, automated tools tweak replenishment thresholds, balancing volumes across sites and preventing stockouts.

Openbravo WMS offers a comprehensive solution for precise logistics management. The Colvin brand, which utilizes this tool, has reduced its goods losses by 50%, thanks to enhanced order traceability. Learn how our WMS supports brands in meeting the demands of unified commerce!

Future trends in logistics automation

Emerging technological advancements

The rising integration of generative AI within management systems promises more refined decision-making in logistics, enabled by its capacity to analyze vast data volumes. For instance:

- Proactive redistribution of storage;

- Reconfiguration of delivery routes based on weather conditions;

- Early detection of stockouts.

Simultaneously, logistics infrastructures are digitizing with IoT and 5G, providing ultra-precise flow tracking. Such an evolution fosters the development of a “self-regulating” logistics system, where all components (machines, products, operators) communicate in real-time to automatically adjust their actions.

Challenges faced by logistics managers

While logistics automation offers substantial opportunities, its implementation can evoke concerns. Transforming processes and evolving internal roles may cause resistance if not properly managed.

To address logistics challenges, partnering with an experienced provider is crucial. Orisha Commerce delivers, through Openbravo WMS, a robust, modular platform tailored for unified commerce. This solution is complemented by comprehensive support, including team training, continuous assistance, and process customization according to real operational needs.

The growing role of artificial intelligence in the sector

AI brings learning, prediction, and autonomous decision-making capabilities to logistics automation, leading to the emergence of a smart supply chain. This means systems can anticipate stockouts, optimize replenishment, and detect anomalies well ahead of impacting business operations. AI also enhances resource management by processing diverse data (sensors, order histories, customer behaviors).

Moreover, AI bridges logistics and customer experience. With smart personalization and search algorithms, Tweakwise enhances product recommendation relevance by factoring in real-time stock availability and logistical constraints.

Logistics automation turns the warehouse into a dynamic performance hub, adept at meeting customer expectations and handling market unpredictability. To maximize this transformation’s benefits, it is vital to employ a robust, integrated, and scalable technological solution, coupled with expert support to ensure secure deployment at every stage.

Frequently asked questions

What are the different types of automation?

- Physical automation: comprises robotic equipment such as conveyors and autonomous mobile robots for handling goods;

- Software automation: utilizes systems like WMS or inventory management software;

- Decision-making automation: leverages AI for systems to anticipate needs, plan flows, or automatically trigger alerts.

What are the benefits of logistics automation?

Logistics automation offers:

- Faster operations and reduced costs;

- Enhanced reliability by minimizing human errors;

- Efficiently managing physical flows (sorting, storage, pallet movement).

Which logistics processes can be automated?

Numerous logistics processes can benefit from automation, such as:

- Goods receipt;

- Inventory management;

- Order preparation;

- Sorting and shipment;

- Returns management.